Architecture to connect everything

All Odeon modules and components are dedicated to one mission: to intelligently network all printing and finishing machines, software systems and workflows within a printing company. No matter which manufacturer they come from, how old they are or whether they are still purely analogue or can already communicate digitally.

The Odeon modules - from the Odeon Connect Box and the Odeon Worker to the Visualiser and Control applications - interlock precisely like cogwheels and can be put together according to the company's requirements.

If all modules are installed correctly, all performance data is visible on a single interface. Data can be recorded, processed and, if necessary, moved centrally - and recurring tasks and processes can be easily automated. Weak points can be recognised before they have an impact, and the in-depth analysis can increase overall efficiency, reduce costs and significantly increase competitiveness as a whole.

Five modules and one communication standard for your "Galaxy of Print"

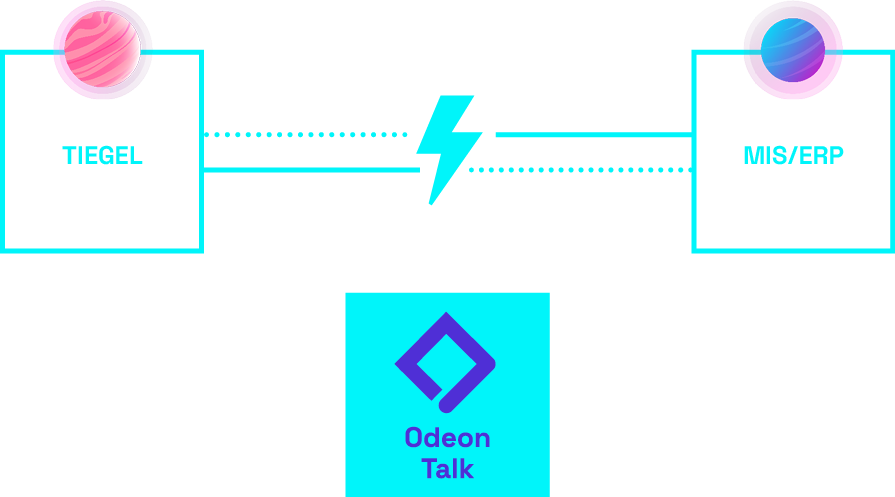

Odeon Talk is not a separately selectable module, but rather a new communication protocol for the exchange within all machines and systems connected to the Odeon platform. Similar to the "universal communicator" in science fiction films, Odeon Talk's task is to "translate" all production data into standardised communication without loss or complication, regardless of the respective "machine language" - in both directions, away from the machine and towards the machine. This makes Odeon Talk the centrepiece and basis for everything that the Odeon integration platform makes possible. As the new industry standard, the communication protocol overcomes all barriers caused by different programming languages or systems.

Worker

Workers are the core module via which all interface-capable printing and finishing machines are integrated into the Odeon platform. From a purely technical point of view, these are interfaces that have been developed by Tessitura specifically for the system to be connected and enable the bidirectional exchange of information with the dashboard - the Odeon Visualiser - and the production control system (Odeon Control). In the context of the "Galaxy of Print", the Odeon Workers can be imagined as small shuttles that enable lightning-fast communication with all machines thanks to the Odeon Talk translation protocol.

Connect Box

Machine parks are often heterogeneous, which means that not all production machines have digital interfaces to be connected via Worker in Odeon. While it was previously not possible, or only partially possible, to integrate decades-old but still frequently used "heavy metal", such as the Heidelberg platen or cylinder, into an overall workflow, the Odeon Connect Box makes this child's play. The Odeon Connect Box is a physical IoT component that is attached to the analogue machines, measures the performance via sensors and transfers the data about the respective print job to the cloud-based Odeon platform. This enables seamless data integration and puts the analogue digital heartbeat into practice.

Visualiser

All production data, metrics and KPIs are recorded and displayed on the Odeon Visualiser in real time and on a user-friendly dashboard interface. This makes it possible to quickly recognise how overall production is in the company, where weak points are or - on the contrary - where trends are emerging. Thanks to the Odeon Visualiser, decisions such as a new investment or a reorganisation of the machine layout can be made on the basis of the current production data. The dashboard can also be accessed remotely from any location.

Control

The Odeon Control module is based on the worker interfaces and the Odeon Visualiser and is the real centrepiece when it comes to controlling production and job data. Machine parameters can be adjusted as required or print jobs can be moved to other systems or even locations - in real time. Odeon Control can be used to automate recurring processes, define customised metrics and performance reports, identify and proactively avoid weak points and create individual notifications.

Display

Anyone who wants to get an overview of the performance data directly on a production machine can install the Odeon Display, another hardware component in Tessitura's Galaxy of Print. All important production data can be shown in real time on the Odeon Display, which can be installed across all manufacturers. This gives operators and production managers a direct overview of the current status of the machines, even in the pressroom.

The Tessitura Analogue Digital Heartbeat overcomes time warp

With the help of the five modules, Odeon not only networks modern production machines with each other in a central platform, but also solves a major problem that has stood in the way of efficient and automated print production up to now: thanks to the Odeon Connect Box with the associated sensor technology and the Odeon Worker, all machine generations - whether old folding or cutting machines, platens or cylinders - can be integrated into a common platform with modern production systems.

12 Odeon advantages

Seamless data exchange between MIS / ERP and production

Real-time display

of all production-relevant data

Identification and implementation the intelligent, flow-controlled automation of recurring processes

Support for the operator in order handling thanks to a planning front end

Reliable post-calculation by recording all production data

Identification of weak points

and early countermeasures

Recognition of trends within the production and order structure

Decision support

by analysing the current production data in detail

Cost reduction

through higher automation

Greater flexibility,

to respond quickly to changes in customer requirements

Entering the megatrend

Mass customisation

Freeing up resources,

which can be used for the further development of the business model

Odeon Talk is not a separately selectable module, but rather a new communication protocol for the exchange within all machines and systems connected to the Odeon platform. Similar to the "universal communicator" in science fiction films, Odeon Talk's task is to "translate" all production data into standardised communication without loss or complication, regardless of the respective "machine language" - in both directions, away from the machine and towards the machine. This makes Odeon Talk the centrepiece and basis for everything that the Odeon integration platform makes possible. As the new industry standard, the communication protocol overcomes all barriers caused by different programming languages or systems.

Tessitura, be.print, ctrl-s, rissc solutions and calibrate: five solution providers who are experienced specialists in their field have joined forces to form the Mass Customisation Crew (MCC) in order to support print service providers and corporates with their own print departments in implementing process-optimised, highly automated and networked production, thereby facilitating their entry into the mass customisation megatrend. The Mass Customisation Crew is neither an association nor a club, but rather a promise by the five specialists to their customers that they will always find a solution to their challenges and questions - even if it may not lie within their own spectrum.

This message is received

Stefan Schifferdecker,

Consultant at Tessitura GmbH

Curious? Then we should talk

With Odeon, we help you to intelligently and consistently network, automate and digitally transform all process steps in your company. Simple, transparent, scalable - no matter how old your machines are or which manufacturer they come from.

Let's go on a mission together and talk about how we can help you discover your "Galaxy of Print". Arrange a quick and uncomplicated meeting with us!